Toroidal Models (EC)

Main features

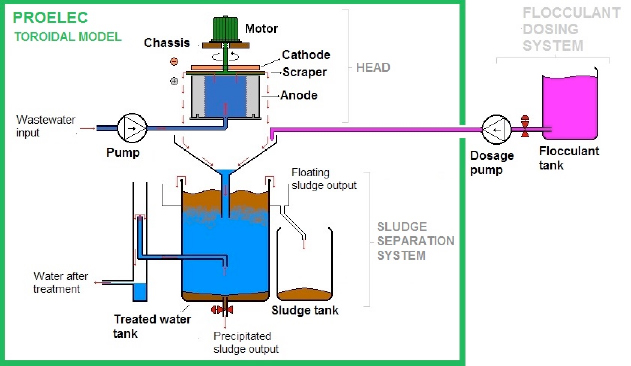

The diagram illustrates the structure and functioning of the system.

This system consists of basically 2 parts: the head and the sludge separation system.

The head consists of the anode – which rests on the frame of the system – and the cathode, which is attached to a mobile structure with a pneumatic piston that allows the anode to be repositioned rapidly. A 1 mm thick scraper is situated between the anode and the cathode. The scraper is attached to the motor axle and it is for removing the sludge that adheres to the electrodes and ensuring uniform wear on the anode.

The anode is toroidal in shape and has a cylindrical concentric cavity inside. The water being treated is driven by a pump towards the lower part of the anode. As a result of the action of the inlet pump, the internal cavity of the anode fills with water until the water overflows at the top, passing through the 1 mm gap between the anode and the cathode. This is where the water electrolysis process takes place.

The water that overflows between the anode and cathode is collected in the lower part of the system using a conical funnel (depending on the model). It is at this point that if it is necessary, the flocculant is added using a dosing system that consists of a storage tank and a peristaltic pump regulated by the programmable controller. Lastly, the treated water flows towards the sludge separation system where it is stored in the treated water tank and the floating sludge, precipitated sludge, and clarified water are separated.

The floating sludge is sent to be decanted into a second tank to be extracted later on. The precipitated sludge is discharged via a manual or automatic valve installed on the treated water tank. The treated water is extracted using a simple separation system.

The main operational problem of some other electrocoagulation systems, arises from the decommissioning of the anode as a result of the formation of a coating formed by the products of the reaction. The insoluble hydroxides can gather on the surface of the anode, thus impeding the electrocoagulation process.

In order to prevent this problem from occurring, this reactor is designed in such a way that the water being treated flows past the anode and cathode, thus enabling the electrocoagulation process and, at the same time, automatically cleaning the anode to considerably reduce maintenance needs.

Contact

If you need information or have any questions, We will be happy to assist youContact with us for more information