Process for selecting the appropriate treatment plant

- Electrocoagulation tests

- Electrooxidation tests

- Chemical consulting

Despite the more than 500 laboratory tests endorsing our significant experience, in many new cases it is advisable to be able to test each wastewater individually. Each case to resolve is virtually unique and has a unique solution.

With a sample of 5 litres of water we can run a laboratory test, near without any cost for the interested party, and this can give us a lot of information, even at a visual level. If analyses are needed to exactly define the degree of removal of pollutants, they are carried out in our collaborating laboratories at a reasonable market price according to the parameter to be analysed.

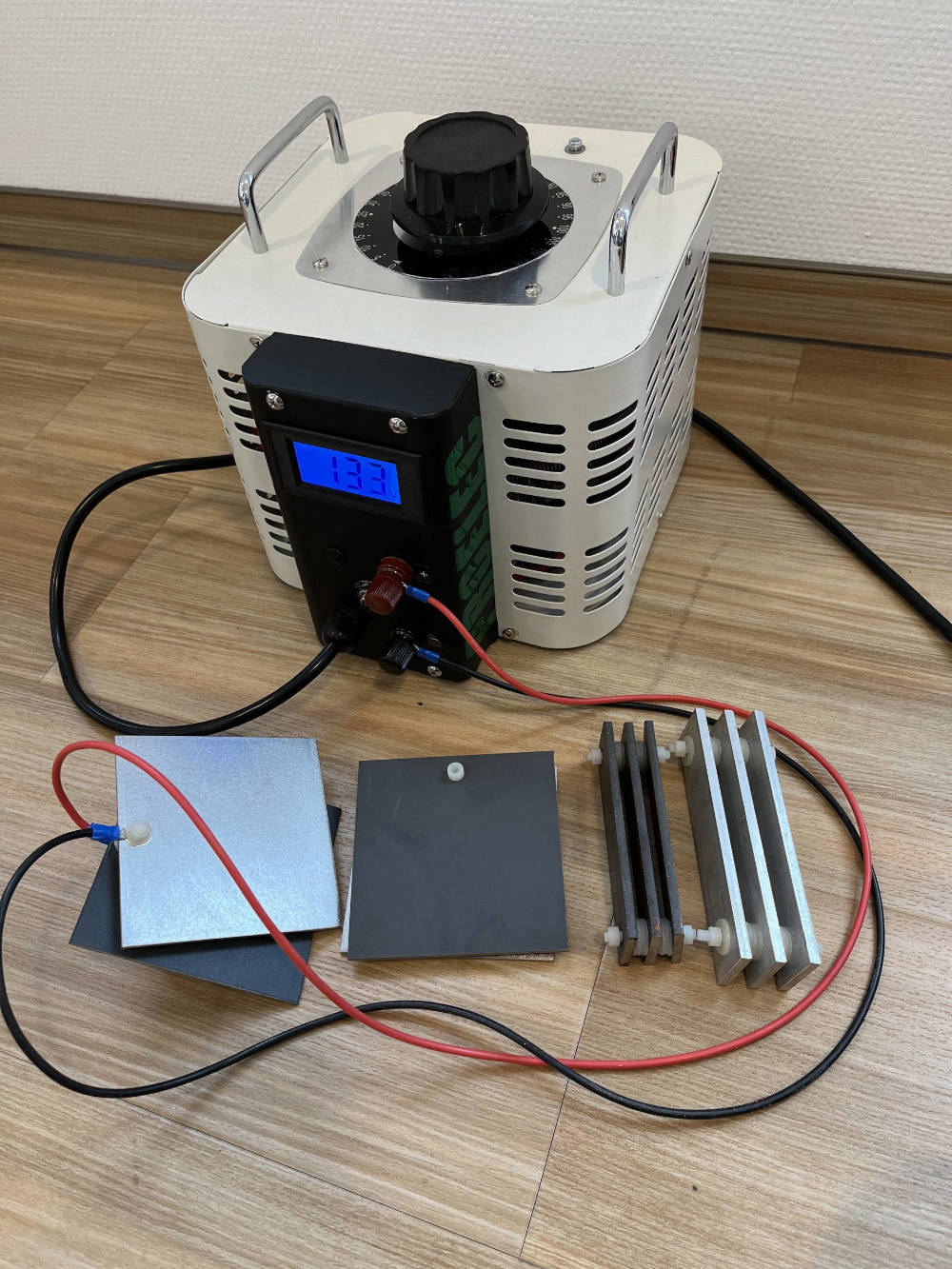

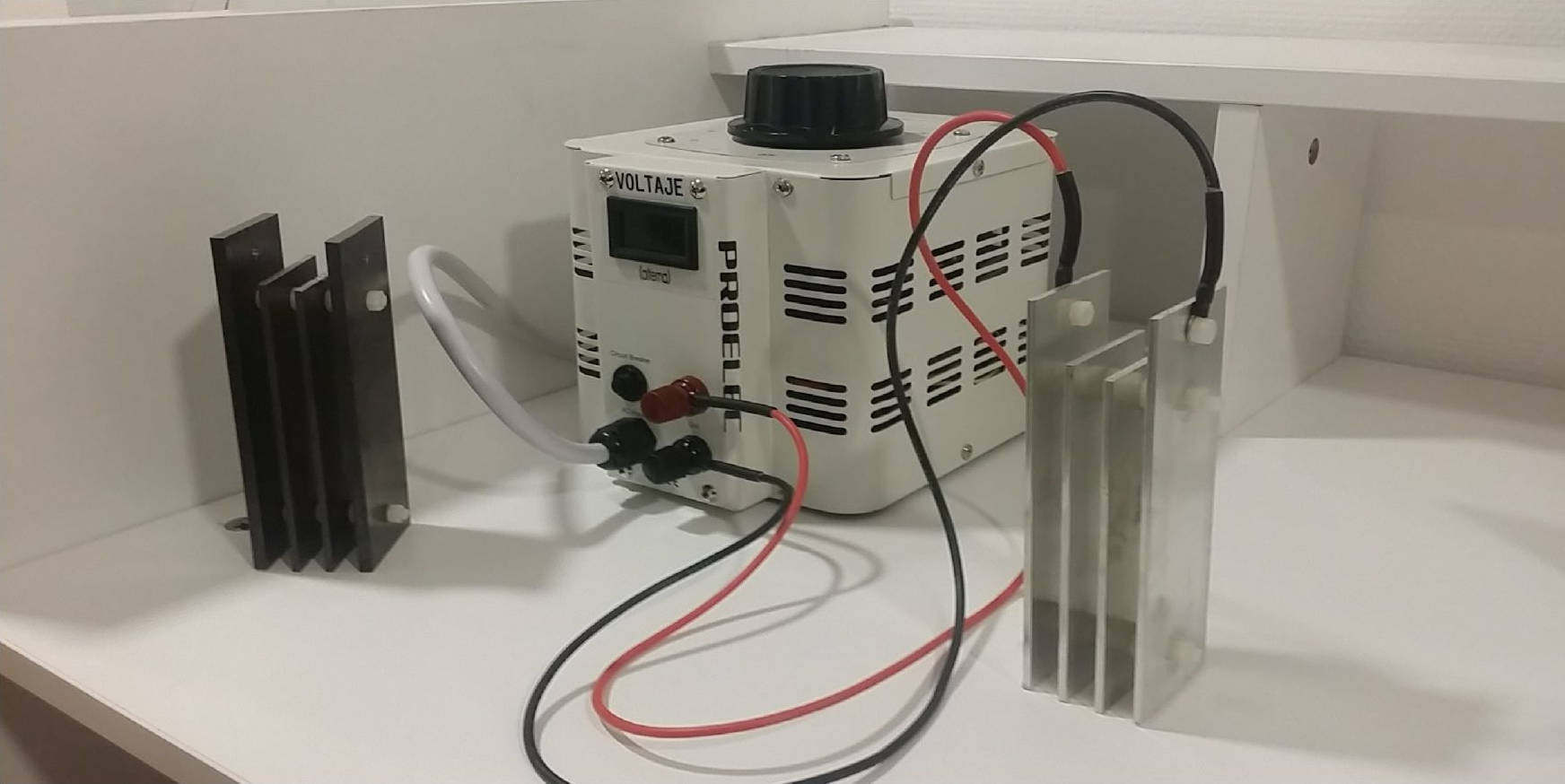

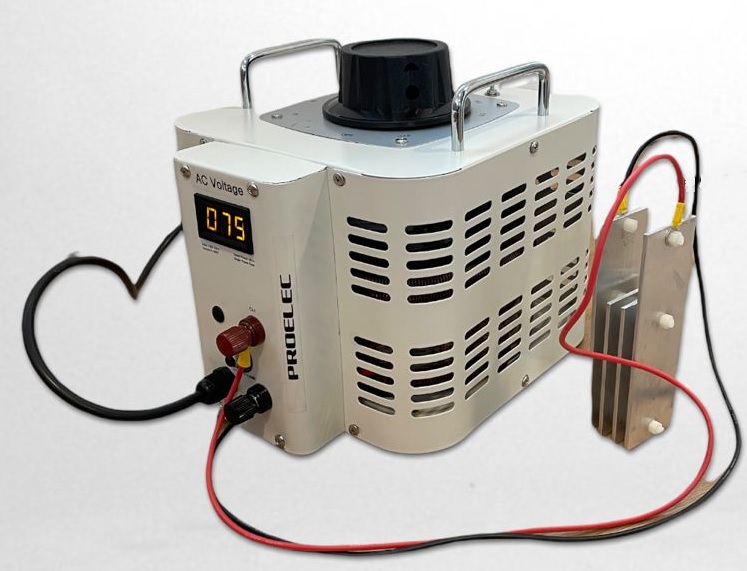

We execute Electrocoagulation (EC) treatment using Aluminium and/or Iron electrodes or, Electrooxidation (EO) treatment using Bored Doped Diamond (BDD), TiMMO, Graphite,… electrodes. Or we execute both treatments (EC+EO) in case that it’s necessary.

These samples can be sent to our premises in northern Europe, near Köln / Bonn (Nordrhein-Westfalen, Germany) or in southern Europe, in Barcelona (Catalonia, Spain).

With this test, the relevant calculations are made to identify the appropriate PROELEC plant, and also the pre- and post-treatments are proposed to the client, if they are necessary for the correct overall treatment.

Depending on the type of water / fluid to be treated, basic EC / EO treatments may not be sufficient. In these cases, we can carry out a complete chemical consultancy to delve into the possible solution via electrochemistry, for example, making adjustments to pH, conductivity, temperature, or add some reagent, change / mix electrode materials, perform different sequential electrochemical processes, etc., leading to a successful treatment solution.

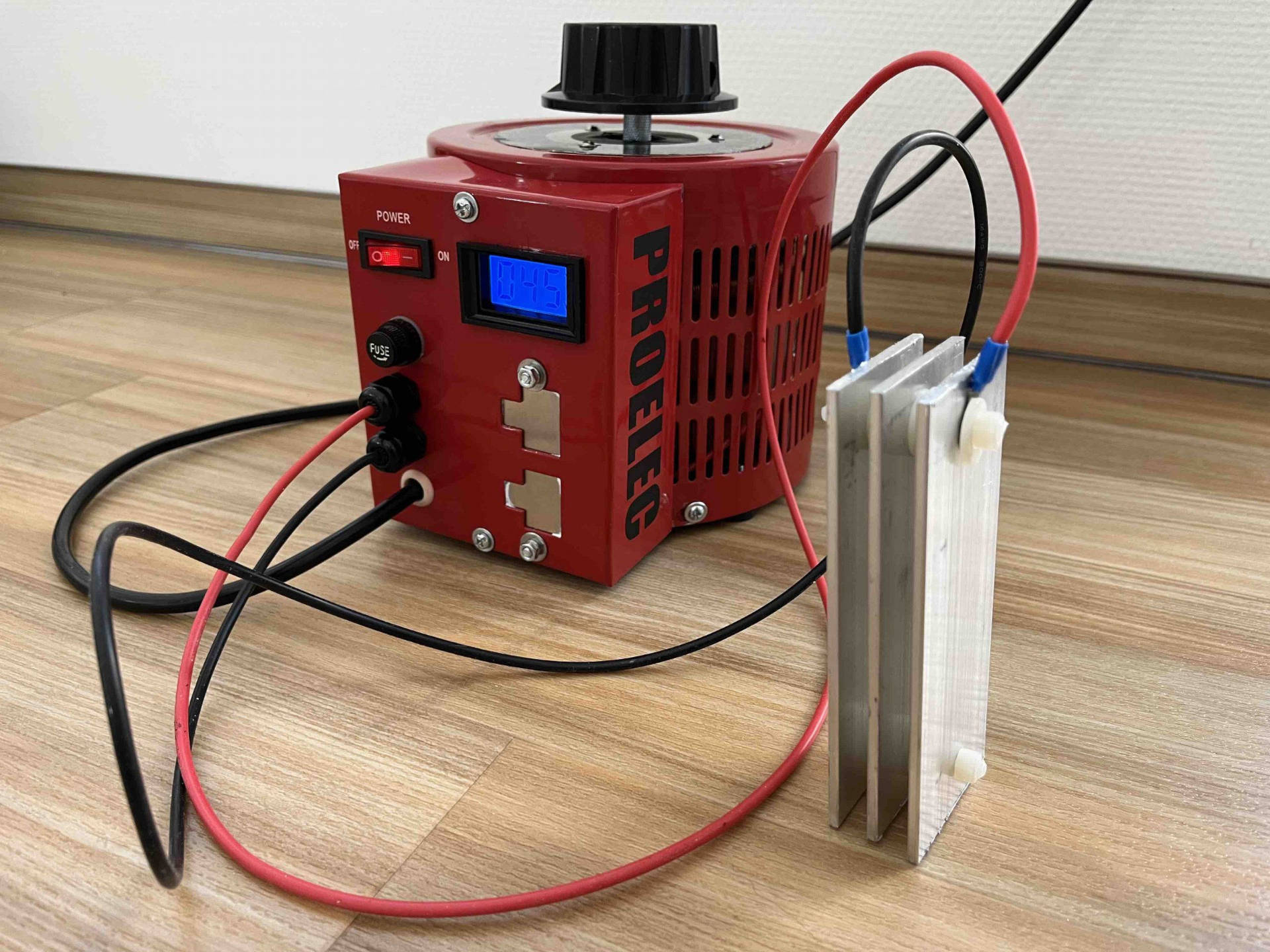

Knowing that nowadays it’s not easy to send even only 5 liter of a sample of water around the world, we supply lab test units, too, in order that the interested party can do the tests fast and easy, for itself or, for their clients. With the lab test unit supplied, we include some tips on how to scale to the industrial plant.

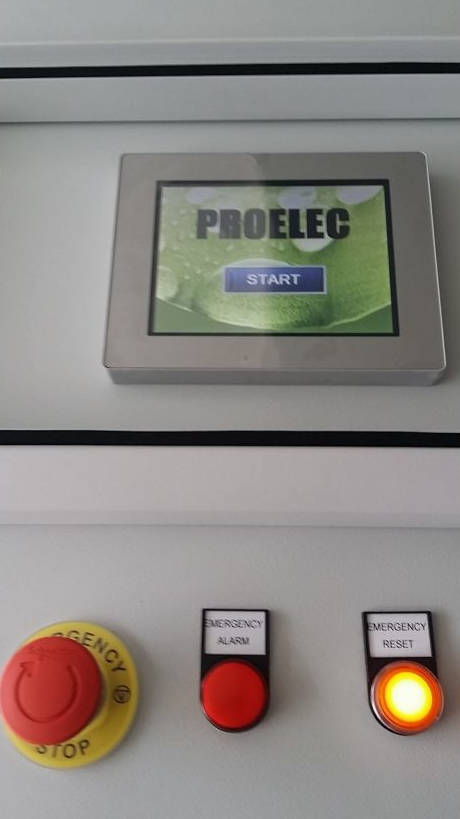

Finally, we offer tests on-site. We send a pilot plant consisting of one stand-alone reactor of around 500 liter, a complete command desk with control and power system, all the connections, and a „Fast Setup and Work“ Guide to start the tests easy and immediately, all correctly packed with wood boxes to reuse and, return the pilot plant back correctly.