What is PROELEC?

And what makes the difference?

Experience and flexibility

PROELEC are treatment plants made up of a set of consolidated, flexible and adaptable equipment, resulting from many years of engineering and development, where each detail has been carefully improved over time. Dimensions, selected materials, instruments, equipment, types of connections, mechanical, electrical and pneumatic installation; system integration, electronics, software,.. everything has a reason and a motive, which means we can guarantee the most efficient, robust and reliable treatment.

Multiple models and setups

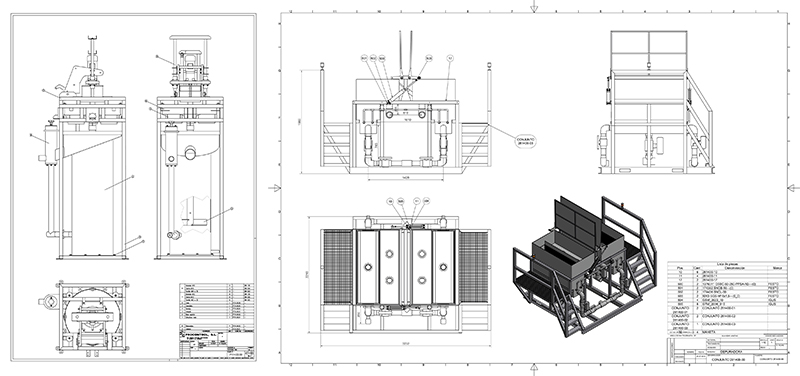

The flexibility and variability of our PROELEC designs, allows setting up systems for treating very small flow rates of a few litres per hour, to treating flow rates with hundreds of m3 per hour, with very different polluting loads.

Exclusiveness

Various patents and industrial know-how make PROELEC an exclusive, quality product.

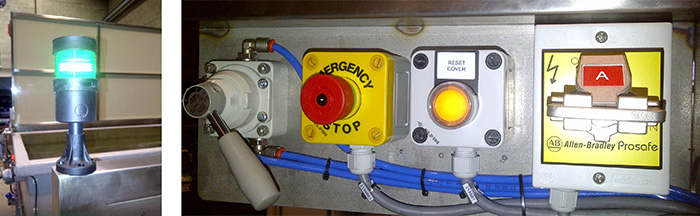

Safety

The various models making up the PROELEC treatment plants guarantee user safety and system integrity, whether they are technical operators or maintenance operators, always according to the European machine safety legislation. Guaranteed maximum levels of safety: PL e/Category 4 conforming to EN/ISO 13849-1 and SILCL 3 conforming to EN/IEC 62061

Solution and reliability

PROELEC has been used in multiple applications substituting equipment or plants by other manufacturers in this technology that have failed due to inappropriate engineering, manufacturing and application, leading to wastewater treatment plants that are impossible to maintain, with low performance and which are very difficult to operate.

Care and cleaning

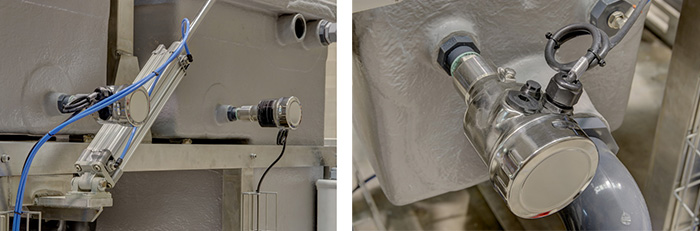

PROELEC cleans the electrodes automatically and in a different way: by inverting the polarity and/or mechanical/pneumatic cleaning elements, depending on the electrodes used. This facilitates the tasks of maintaining and preserving the function of the equipment, and also maintaining a high performance of the treatment over time.

Economizing: electrocoagulation and sludge separation in a single equipment

The PROELEC Toroidal plants include sludge separation, a fact which substantially economizes the overall treatment of a certain effluent. These designs include the electrolytical cell and the corresponding subsequent separation of sludges in a single structure.

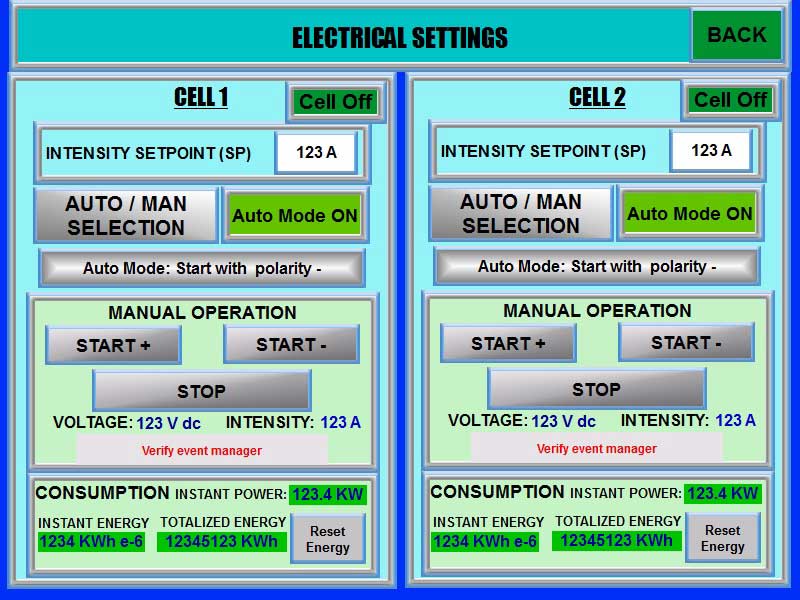

Total automation and integration

The PROELEC control system is made up of a central control system, to which other control systems are integrated, that are independent of each other, and particular and specific to each of the various reactors or electrolytic cells in each solution. These independent control systems are intended for specifically and appropriately controlling the power applied in the reactor or electrolytic cell, to carry out the correct treatment and obtain the expected results. All this is automated without the user having to worry about operating and safety details. The PROELEC central control system is easy to integrate with other systems that the client may have on its premises.

Applicability in explosive atmospheres (ATEX)

The PROELEC PRO4000Series ATEX plants are intended for use in atmospheres with risk of explosion (ATEX), with minimum marking:

According to the following legal documents and/or standards:

| Directives: | No. and dat of issue of standards |

|---|---|

| 2014/34/EU: Apparatuses and protection systems for use in potentially explosive atmospheres |

EN 13463-1:2009 |

| 2006/42/EC: Machines | EN 60204-1:2006 / CORR 201 ISO 12100:2010 ISO 12100:2010 |

Robustness (High temperature)

The materials making up the PROELEC PRO4000Series reactor are developed to withstand high temperatures during long periods of time, which are usual in this type of treatment, and are caused by the electrical energy contributed to the process and the resulting electrochemical reactions.